Silver Recovery from Scrap and Low-Grade Residue

Topics: metal recycling, electrowinning, emew, Refining, metal powders

Topics: electrowinning, mining, emew, Refining, Refinery Optimization

What pops into your mind when you see the word, "liberation"?

---

The word liberation comes from the latin word, liberatus, which literally means "to set free" or "to deliver", and can easily apply to myriad of different topics from politics and religion to science and industry.

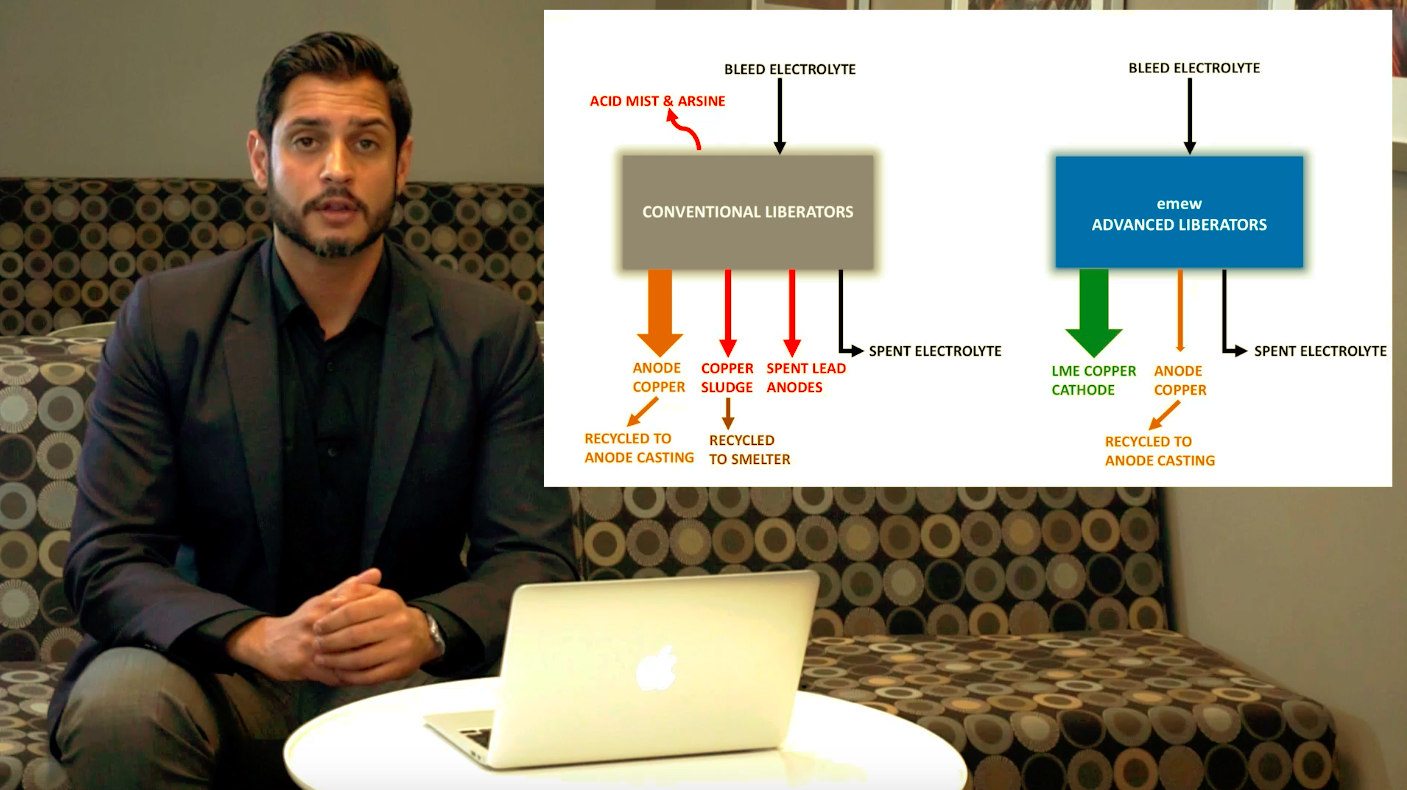

Particularly in the copper industry, the word liberation applies to the act of freeing copper specifically from refinery bleed electrolyte. The process that starts with mining and carries on through smelting and electrorefining is complex with many process operations. Let's take a closer look at the story of 'liberating copper'.

On average, mined ore contains about 1% copper and in order to recover this copper from the rock it requires several physical and chemical processing and refining steps in order to produce market ready copper metal.

Topics: copper, nickel, Refining, Refinery Optimization