FAQ: Operating Cost of emew Electrowinning Plant

Topics: Video

Cobalt and Nickel wastewater: How much money are you flushing down the drain?

Two case studies on the value of metal recovery from wastewater

It’s no secret that industrial pollution is harmful to the environment and human health.

Topics: Wastewater Treatment

In one of the previous posts I described the basic principle of conventional electrowinning. Today I would like to talk about the differences between conventional electrowinning and proprietary emew technology, which is based on fundamental electrowinning tenets but offers so many additional benefits.

Topics: Video

Many industries generate acid mist as a result of their industrial processes. In most cases the acid mist will be caused by usage of inorganic acids, and in particular sulfuric acid. Sulfuric acid is mostly used in a production of fertilizers, and industries like pulp and paper, iron and steel, mining, refining and wastewater treatment. Acid mist is formed as a condensation of acid vapour and the extent of the mist will depend on the industry, process and solution itself.

Topics: Video

FAQ: Types of emew cells and production rate

Topics: Video

4 Most Frequently Asked Questions About emew Cathodes and Anodes

Today we would like to answer some frequently asked questions about

Topics: Video

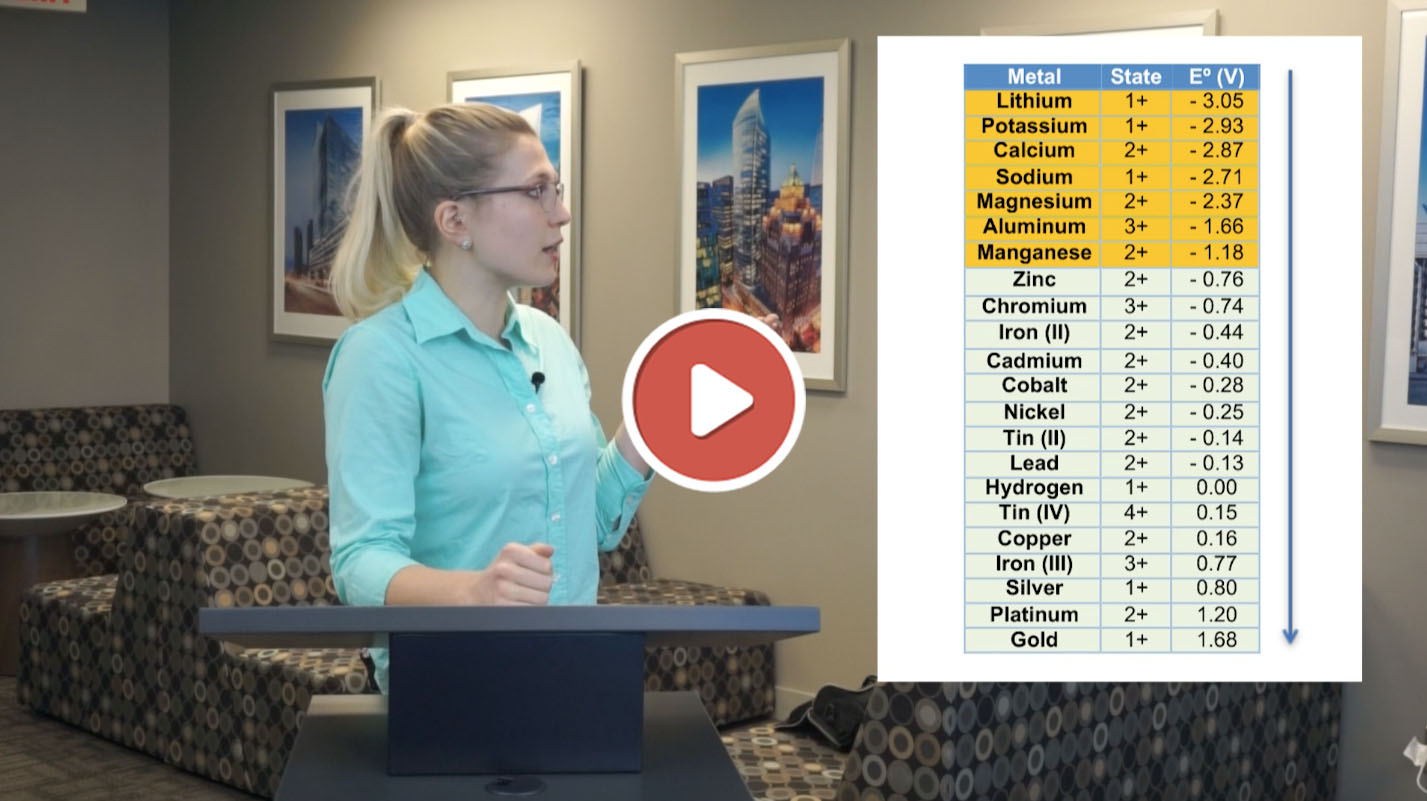

[VIDEO] Why some metals are easier to electrowin than others?

Topics: electrowinning, General

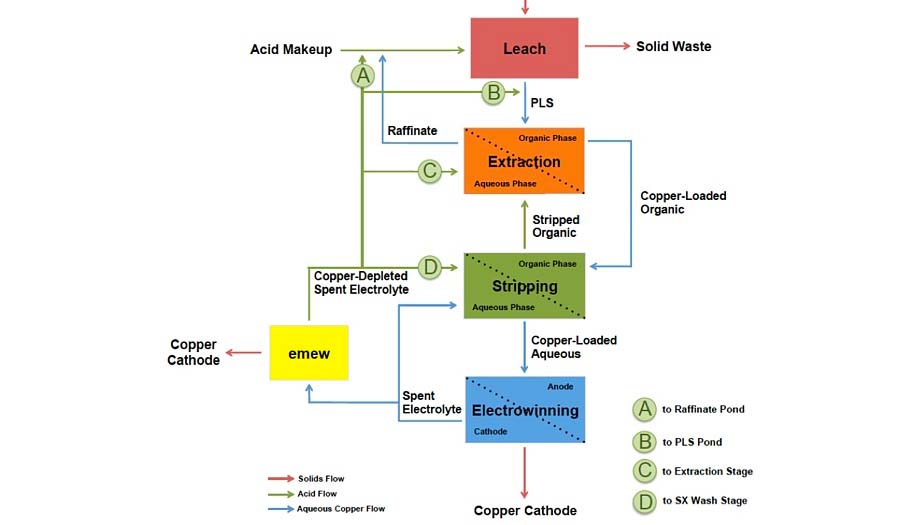

How can you increase the copper recovery of your SX-EW process by 8.9% in only 29 days?

What is SX-EW?

Topics: Refinery Optimization

Silver Recovery from Scrap and Low-Grade Residue

Topics: metal recycling, electrowinning, emew, Refining, metal powders

Can I recover copper from this? Copper recovery from the ground up

A question that we hear from Clients every day is "Can I recover (copper - or other metals) from this?" The material in question can be concentrated wastes, dilute effluents,

Topics: effluent treatment, environmental, copper, Wastewater Treatment, metal recycling, mining, Refinery Optimization, copper recovery, copper recycling