While Elon Musk compares AI to “summoning the demon” and Bill Gates doesn’t “understand why some people are not concerned” that artificial intelligence slowly but steadily becomes a part of our daily lives.

Our mobile phones are equipped with Siri, Cortana or Google Now that assist us with daily tasks. Self-driven cars are already on our roads, driving thousands of miles with ZERO accidents (or at least they are not the reason for the accidents).

Retailers like Amazon and Target use a self-educating software that can anticipate your needs and offer you the next product to buy even before you know you need it.

How about these online customer support chats? Did you know that most of them are machines hiding behind human names? Many of them have the ability to learn and to adapt to the tone of questions in order to search company websites and present the right information to the customer.

“There is huge demand for artificial intelligence technologies. “

Yuri Milner

Even though I’m concerned about the ways humanity can be affected by development of artificial intelligence, I think there is no way around it.

Artificial intelligence is divided into Strong AI and Weak AI. While Strong AI is aimed at doing things the same way people do, Weak AI is any system that can optimize a process or identify trends.

I don’t have any problem with weak artificial intelligence. In fact, I love it! Just imagine the endless possibilities of artificial intelligence when it comes to medical diagnoses or accident prevention in driving.

How about ongoing process optimization and automatic safety regulation for industrial applications? Wouldn’t it be nice if your next wastewater treatment plant had the ability to self-learn and adapt to changing conditions?

Well, we are on it!

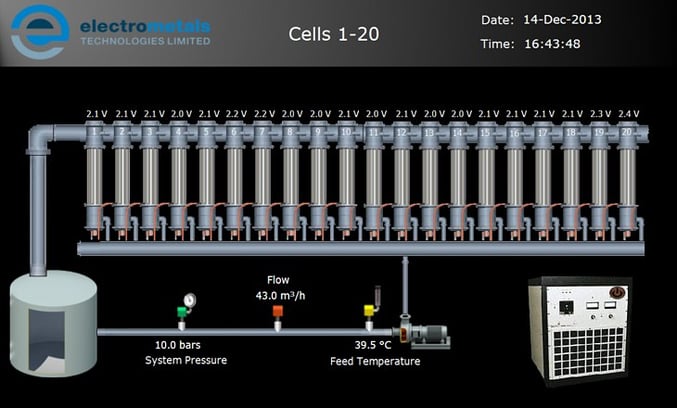

Even today our wastewater treatment and metal recovery systems are able to provide real-time, ongoing monitoring and performance management.

emewNet Remote Management System with Continuous Performance Monitoring helps to eliminate the element of surprise in operation and make the necessary adjustments to the hardware in order to prevent a fault before it actually happens.

Even though our systems are proven through years of operation and customer driven innovation, we are looking to the future of artificial intelligence and working on our next application. Fed from hundreds of sensors that collect real-time information, the next versions of emewNet will be self-educated. They will identify trends in plant operation, create benchmarking data and will let operators know about hardware faults way ahead of time.

In addition, the artificial intelligence of the IDEAL emewNet will automatically adjust the current density, flowrates, temperature all while measuring metals concentrations to achieve the fastest or most efficient conditions to recover metal.

It will also take into consideration electricity costs and consumables, such as anodes, cathodes and connectors to optimize production and minimize operating costs.

In countries with very high power costs, it could even adjust to use less power during peak times and more power during off-peak times.

Of course, some may say that artificial intelligence could be dangerous in the long run or in the wrong hands. But in a real life applications and with limited self-learning abilities AI's can be of great assistance helping us to make our planet greener.