Basics of Cobalt Electrowinning in Under 3 Minutes

Topics: Refinery Optimization

How can you increase the copper recovery of your SX-EW process by 8.9% in only 29 days?

What is SX-EW?

Topics: Refinery Optimization

Can I recover copper from this? Copper recovery from the ground up

A question that we hear from Clients every day is "Can I recover (copper - or other metals) from this?" The material in question can be concentrated wastes, dilute effluents,

Topics: effluent treatment, environmental, copper, Wastewater Treatment, metal recycling, mining, Refinery Optimization, copper recovery, copper recycling

Enhanced methods for nickel recovery from low-grade ores and bleed streams

Way back in elementary school when you thought of nickel, the first image that popped into your head was probably that nice shiny 5¢ coin. Even though we hardly carry change purses anymore, nickel is still ever present in our day-to-day lives. From the shiny stainless-steel trim on your building to the knives in your kitchen, nickel is found everywhere. With nickel becoming favored for use in transport, power generation, cell phones, food preparation, and medical equipment, it leads one to think about where all this nickel is coming from.

Topics: nickel, Refinery Optimization

Tea & Metal Recovery: An Unlikely Comparison

What do your morning cup of tea and a metal recovery plant have in common? Not a whole lot, is what you would hope! However, this is where you are mistaken. The simple act of steeping tea is, in fact, very similar to the process of leaching in metal recovery.

Topics: Leaching, Refinery Optimization

10 Questions Answered About Electrowinning and Electrorefining

1. What is electrowinning?

Topics: electrowinning, Refinery Optimization

In a world that is increasingly demanding sustainability, nonferrous metal recycling has become a very important practice. Opting for recycling does not only mean being responsible for the environment and reducing the carbon footprint, it is also a very reasonable business in industries that rely on using non-renewable resources.

Topics: Wastewater Treatment, metal recycling, electrowinning, Refinery Optimization

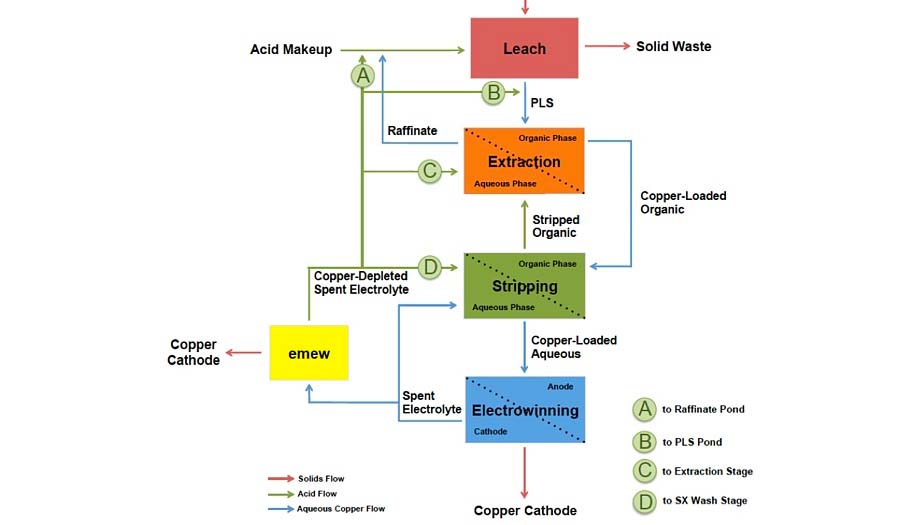

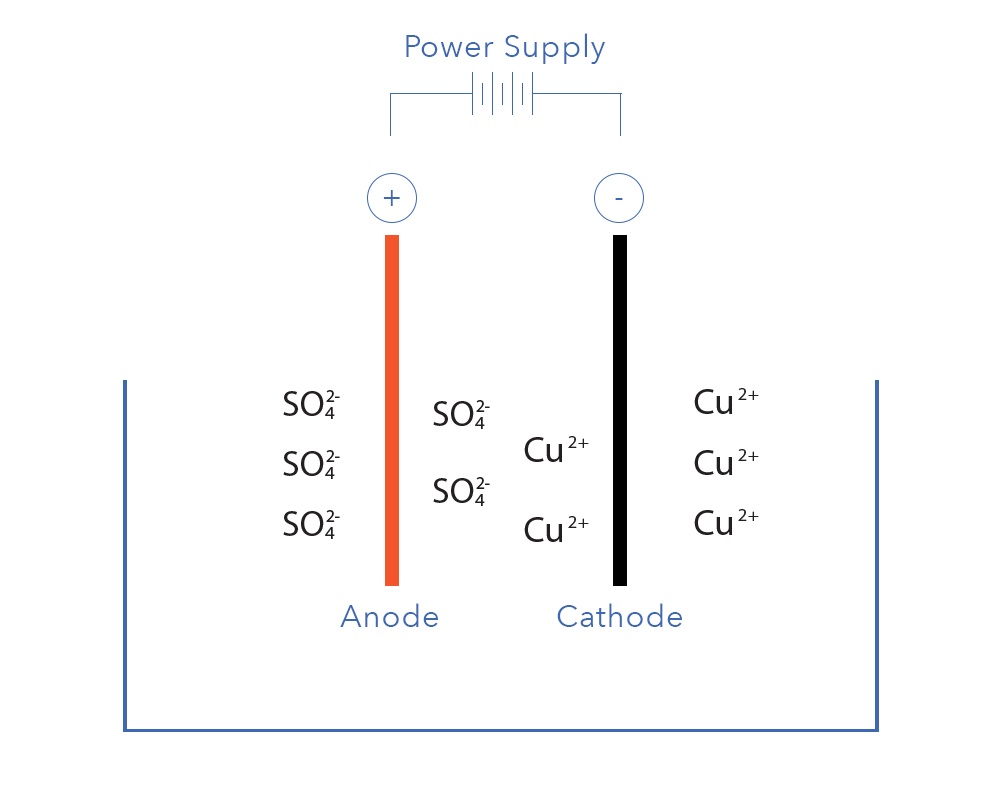

The electrowinning of copper is an electrolytic process that uses electricity to recover dissolved copper from solution as

Cu2+(aq) + 2e- -->Cu(s) (E0 = +0.34V)

Copper easily dissolves in acids including sulphuric, nitric and hydrochloric. Recovering copper cathode from acidic

Topics: copper, electrowinning, emew, Refinery Optimization

Topics: electrowinning, mining, emew, Refining, Refinery Optimization

Electrowinning is known as an electrolytic process because it involves electrodes submerged into an electrolyte.An electrolyte is simply a conductive solution formed by dissolving positively and negatively charged ions.

Topics: electrowinning, emew, Refinery Optimization