As the world is advancing towards clean, sustainable energy sources, businesses in traditional resource industries can be faced with a moral dilemma – to sacrifice margins in favour of clean initiatives or continue using conventional equipment and carbon-based energy sources that ensure revenue maximization.

But the thing is, there might be just a way to do the right thing and reduce operational expenditure.

In this article we will be looking into electrowinning technology as a candidate for clean energy usage.

Depending on the location and the application, this analysis can be applied to other industries and technologies as well.

To download fill the form below

The purpose of this analysis is to explore the financial implications of powering an emew electrowinning plant with solar energy instead of grid power, or a diesel generator when grid power is inaccessible such as in remote locations.

The goal here is to produce clean metal at low-cost. My assertion is that it is possible, especially in the countries that get many sun hours throughout the year.

For example, in most parts of India, clear sunny weather is expected 250 to 300 days a year which makes this area ideally suited for power stations based on solar energy.

Interesting enough, it just happens to be that the biggest producers of copper worldwide are also located in the regions with the most sunlight hours. To name a few – Chile, Peru, China, USA (Arizona), DR Congo, Australia, Zambia, Indonesia, and Mexico.

Before we start our analysis, let’s make a few assumptions about the power consumption of the electrowinning plant.

In order to efficiently operate our mid-size electrowinning plant, we will need enough power to feed emew cells, pump, control computer, battery storage to help maintain voltage profile, lights, computers, and other auxiliary equipment.

After adding up all the components, we get about 130kWhr of power, normally a combination of AC and DC.

It is also important to say, we assume for the purpose of this exercise that the electrowinning plant is operational ONLY during the day time, and only when there is enough sunlight for energy to be generated.

Solar vs Grid Power

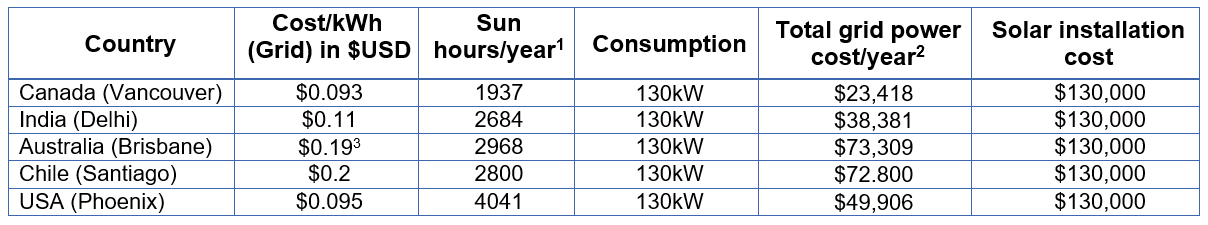

First, let’s calculate how much we would pay for grid electricity compared to solar, based on the same number of operational hours in a year.

For this calculation we checked a few different locations – Canada (our home), India, Australia, Chile, and USA (Arizona).

Also, we know that the average price for a commercial solar plant of this size is about $1000/1kW of power. This means that we would pay about $130,000 USD for our solar plant.

Now, if we were to run our solar-powered emew plant and grid-powered emew plant for the same number of hours we can calculate the payback time for each country.

1Based on average values provided by Wikipedia. 2For the sake of the comparison we assumed that the plant was operational for the same number of hours as sun hours available in a given area. 3Based on discounted rate for Business Every Day Saver (https://www.energyaustralia.com.au/business/electricity-and-gas/small-business/plans).

In Canada it would take about 5.5 years to pay for the solar plant installation, while in India it would take 3.4 years, compared to 2.6 years in Arizona, and only 1.8 years in Chile and Australia.

This seems like pretty good payback in India, USA, and Australia. With electrowinning plants averages about 15 years of operation, we can get 12 or more years of free electricity with a potential savings of $600,000-$900,000 USD. Numbers like this can kill or revive a project.

But, keep reading… It gets even better for diesel power in remote locations.

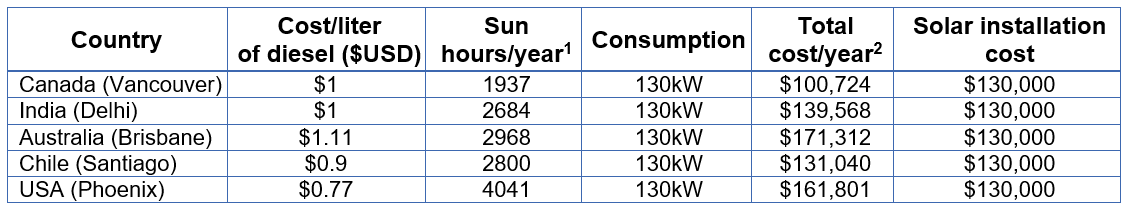

Solar vs Diesel Generator

In many cases, a small mining operation will be located in remote areas without connection to the grid, and they have no other choice but to use expensive and dirty diesel for energy production.

So, why not solar?

As a rule of thumb, a diesel generator uses 0.4L of diesel per kWh produced. In our case we need 130kW, meaning 52 litres of diesel per hour of operation. If we multiply this by the cost per liter and number of hours of operation per year, we arrive at the total cost of diesel for the year.

1Based on average values provided by Wikipedia. 2For the sake of the comparison we assume that the plant was operational for the same number of hours as sun hours available in a given area.

Let’s look at the payback.

Given that the electrowinning plant powered by solar is running the same number of hours as the one powered by diesel, we get quite interesting results.

Only in Canada the payback would take a little over a year, while in all other locations that we checked we would pay for the solar plant installation in less than a year. This is very impressive!

We don’t just save a lot of money on diesel, but also produce clean energy and can proudly claim that the metal produced is “clean metal”.

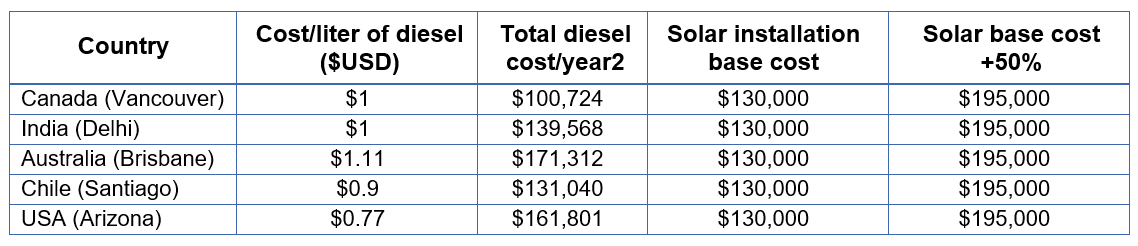

It is important to mention that an additional grid forming element, such as additional battery storage, might be required in order to sustain grid voltage and frequency. We may also need additional panels to operate the plant while the battery is charging.

Let’s say we will need to increase our cost by an additional 50%. How will this affect the payback?

Even in the case of the increased cost of a larger solar plant, we are still getting less than 2 years payback for all the locations that we analyzed.

As you can see, solar energy can be a viable alternative to produce clean metals in remote areas. And it can contribute to both, financial and sustainability goals.

Have a question about your metal recovery needs? Give us a shout.